Electro Harmonix SSD repair

Somebody had noticed I had done some repairs on my own gear and asked me if I could take a look at an EHX Super Space Drum that wasn't working.Symptoms were that it started to not trigger well until it finally gave up and refused to trigger at all. I had absolutely no idea what could have caused it and my initial thought was some sort of bad connection or other mechanical problem.

I had never repaired anything for someone else and I didn't have any pressure on me really. It was more of a "just see if you can do something about it" request, so I thought it'd be fun to give it a shot!

Unfortunately I forgot to take a picture of it so I'm using a frame of a video clip I made with it :)

|

| The picture is from AFTER I had serviced it. Read on if you're curious about the alligator clips to the left. |

Opening it up and finding problems

Ok, so the guy told me the problem was that the thing didn't trigger.(From now on I will refer to the Super Space Drum as simply "SSD", not to be confused with solid state drives ;) )

He also told me that the previous owner had removed a power supply jack and replaced it with an internal transformer suitable for our 230V mains voltage, so you had a 230V cable running into it.

I had never seen one of these things before, had no idea what is was or how it worked, but I opened it up and had a look.

This is the transformer on the inside:

Not a very nice way to mount it.

But actually, the owner told me that he had put the duct tape there to keep it in place. When he got it the transformer was just loose on the inside! It was just wrapped in some electrical tape to insulate it...

Furthermore, there's no strain relief on the cable...

Observant readers will notice a small white grain inside the case, next to the hole where the mains cable enters the case. I'll get back to that later :)

You can also see a white piece of double adhesive foam tape. The sensor used to sit there but I had removed it already when the photo was taken.

Since the problem was that it didn't trigger, I was curious about what the actual trigger was. I found something attached to the case, somewhere behind the leather pad with the "Space drum" text.

I assumed this was the trigger and decided to remove it.

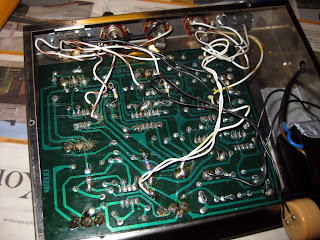

Here's a somewhat crappy picture of the inside, but with the sensor visible after I had removed it from the adhesive stuff but still had the wires attached to the PCB:

|

| Note the white particle next to the hole again :) |

Here you see the beige-brownish trigger just hanging in its wires.

It looked like an old microphone capsule of some sort. The first thing I noticed after removing it from the tape was that it was rattling inside. As I shook it a bit, something fell out.

The white stuff next to the hole in the case :)

It turns out that this is indeed a microphone. More precisely a crystal microphone, which most likely used a Rochelle salt crystal, having piezoelectric properties. So, that white stuff was the salt.

It was easy to conclude that the trigger microphone was busted :)

To convince myself, I checked the microphone output with an oscilloscope as I tapped it, but got absolutely zero signal from it. It was dead.

The final problem I saw with the SSD was that the power LED was really dim. I could barely tell if it was lit or not.

Fixing

Trigger

First thing on the agenda was to fix the trigger as that was the only "real" problem.I managed to dig up some schematics and also found out that it should be possible to replace the microphone with a regular piezoelement. So, I did that and tested it a bit. It worked!

The piezoelements are really sensitive and I wasn't sure if it would be too sensitive. I had put a rather large sensor there and temporarily fastened it to the case next to where the microphone used to sit, but I got the SSD to trigger just by tapping it even with the sensivitity knob turned all the way down.

Luckily I had bought 3 different elements and this was the largest one of them (35mm diameter) so I took the next size (20mm) and tested that. It was a bit less sensitive and worked well, so I decided to keep it.

There were no wires soldered to the piezoelements when I bought them so I had to do that myself. To protect the wires from breaking off or moving around too much I applied some hot glue.

A friend of mine had some double-adhesive foam pieces, like the one the microphone was attached with so I used one of those to attach the piezoelement to the case, right behind the middle of the leather-pad.

Transformer and power supply

I told the owner that I was worried about the transformer-solution.No strain-relief, 230V straight into a metal case, no fuse, no ground, transformer loose on the inside...

I suggested removing it and replacing it with a DC jack.

He agreed, so I removed the transformer and saw something interesting.

Originally, there's supposed to have been a small transformer, probably for US mains, attached to the side using the two holes on the side. The larger hole where the cable comes in was originally a small screwhole, just like the other one, but it was probably enlarged to fit a jack, as there was a label on the outside saying "24 VAC".

The mains cable would have come into the case through another hole just below one of the switches on the back, but that hole was plugged in a rather nice way that makes me believe it was a factory mod.

The real mystery was that the original transformer should have been a center-tapped 2x12V, which is obvious from the schematics. However, the new transformer was only connected using 2 wires, as you can see in the photos. So it was only using one half of the rectifier in the voltage stabilizer. I assumed it was a simple 1x12V transformer.

Now, the funny part is that as I removed the electrical tape, I saw that it was indeed a center-trapped 2x12V transformer, but it had been bridged to work as a 1x24V transformer. Why?! I will never know...

Also, one wire was connected to where the center-tap should be connected, so instead of getting 12V+12V, the rectifier section got 1x24V... Perhaps that old old "24VAC" modification did the same thing?

Anyway, I removed it, put a 2.1mm DC jack in the larger hole where the cable used to come in and attached the wires to after the rectifier on the PCB. I put a DC plug in it with alligator clips on to test it (which is what you see in the very first photo in this post) and tested it with like 8.9V and it worked.

After looking at the schematic, I saw that it should be able to handle up to 25V on the input, as there was a capacitor there, rated at 25V so I decided that to give it some margin, 9-18V DC should be perfectly safe.

I tested 18V DC and nothing exploded. Nice :)

The scary thing is that with the old transformer, there was actually around 23V coming in after the rectifier stage due to the strange was it was wired. Not a lot of margin there... I'm no expert by any means, but that tranformer modification didn't look safe at all.

Power LED

Finally, I took a look at why the power LED was so dim. The answer was obvious if I compared the schematics to what was in the SSD. The current-limiting resistor in the schematics is a 4.7k resistor.The resistor actually in the SSD was a 47k resistor. No wonder it was so dim :)

So, I replaced it with a 4.7k and it lit up a bit more. I say a bit because I still think it was a bit dimmer than what you're used to I guess. However, as I thought the design was for 12V and I had decided that 18V would be safe, I kept the resistor at 4.7k, just to be safe.

Fixing results

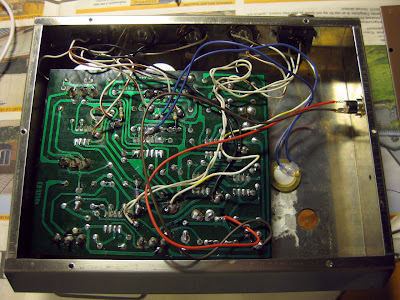

This is a photo of the inside after the repairs and changes were done: |

| Yeah I know, I should have removed the remains of the old tape... |

And here's a picture of the side with the DC jack:

|

| Pretty :) |

Aaaaand I couldn't resist making a youtube clip where I demonstrate it a bit.

I actually used the clip to show the owner what his SSD looked like and to show him that it was working.

Pretty convenient way!

Here it is:

Sorry for writing such long posts... Perhaps it may be of use for someone else some day though :)

Hi mate, nices post. Old one I know but. I would like to ask if you know a way to mod the trigger so it accept trigger from a 606 for example

ReplyDeleteCheers,

jm

Hi, I guess it would be simple to add an input, but I have no answer to give you without experimenting myself (and I don't own a space drum).

DeleteIn theory you probably need to get a trigger pulse to where the piezo element sits so the op amp can handle it and trigger the rest of the circuitry.

I'd start by putting a small capacitor in series with your input (no idea of value, wild guess 10nF) and a resistor as well for safety (100k?) and patching it to pin 3 of the op amp (LM324, IC1 I think). But you won't get varying pitch by using a fixed trigger pulse, so it will be a bit boring, but doable I guess.

The TR606 trigger voltage might be a bit too high for the LM324 so I'm not sure if it would be better with a voltage divider on the input insted of just a resistor in series though...

So instead of a 100k resistor you could put maybe a 22k resistor followed by a 10k trimmer, if you wanna adjust it, and connect it to ground. Then tap the trigger pulse between the resistor and trimmer and patch it to pin 1 of the LM324.

Like I said, hard to say without experimenting a bit, and difficult to explain in text when I'm not sure how good you are with electronics.

Peter, thanks a bunch for your detailed answer. It's really nice. I will check that out!

DeleteI bought a super space drum brand new and the trigger button never worked. Still in its box. Not sure what the problem might be. I’m no good at electronics so repairing it myself is not an option.

ReplyDelete